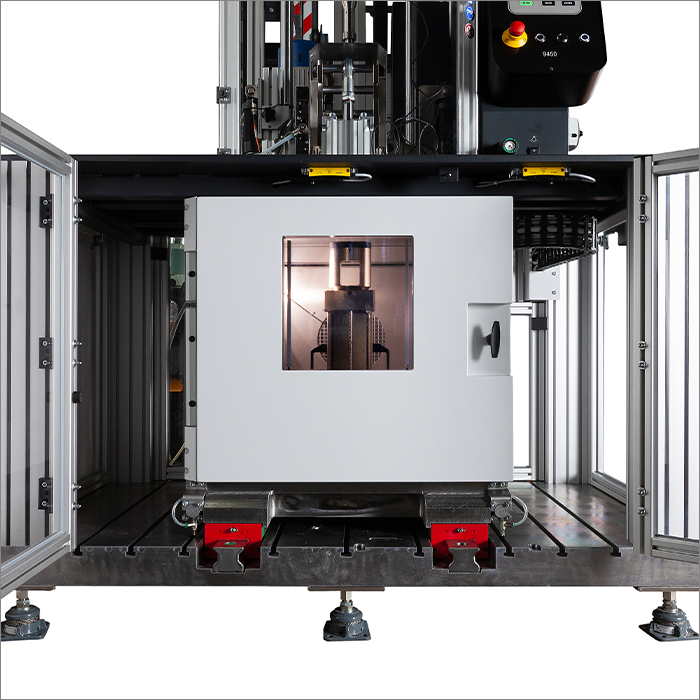

Drop Weight Impact Testing Machine

Impact Tester for Plastics, Composite, Light Alloys and Components

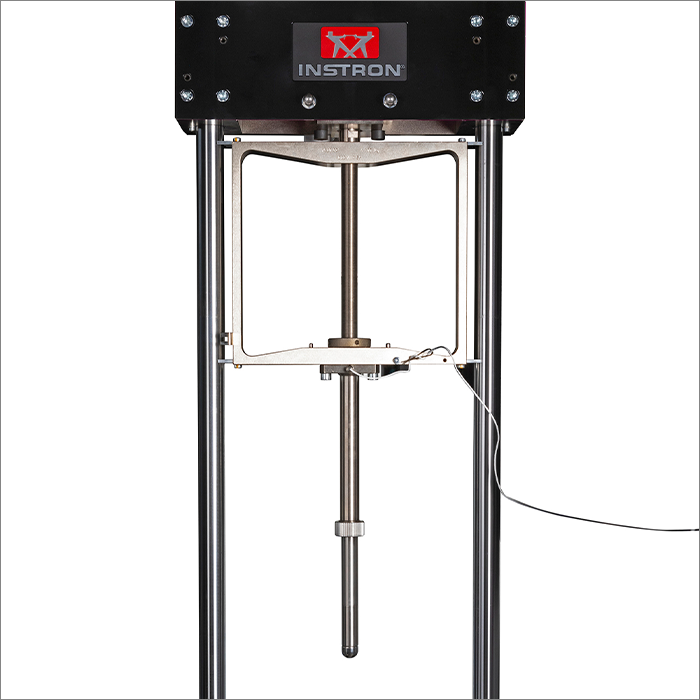

The Instron® 9400 Series drop weight impact testing machine complies with all the main impact testing standards ranging from 0.3J - 1800J

Puncture Test Method and Other Impact Test Methods

Puncture resistance test, CAI test (Compression After Impact), Tensile Impact Test, 3 Point Bending Test and Wedge Peel Impact Test are the most common drop weight impact test methods. They determine the toughness of polymers, load-deflection curves and total energy absorption of impact events. The main ISO and ASTM standards for impact test of plastics are: ASTM D3763 multi-axial impact test, ISO 6603 for the puncture resistance test method, ASTM D7136 for the CAI test method, ISO 11343 for the wedge peel impact test method, ISO 8256 for the tensile impact test method.

SIMPLER

Efficient Drop Weight Impact Testing

The intuitiveness of Bluehill® Impact software with the touchscreen dashboard simplifies day-to-day activities: users are guided through the entire testing process with step-by-step instructions, ensuring tests remain repeatable, simple, and error-free

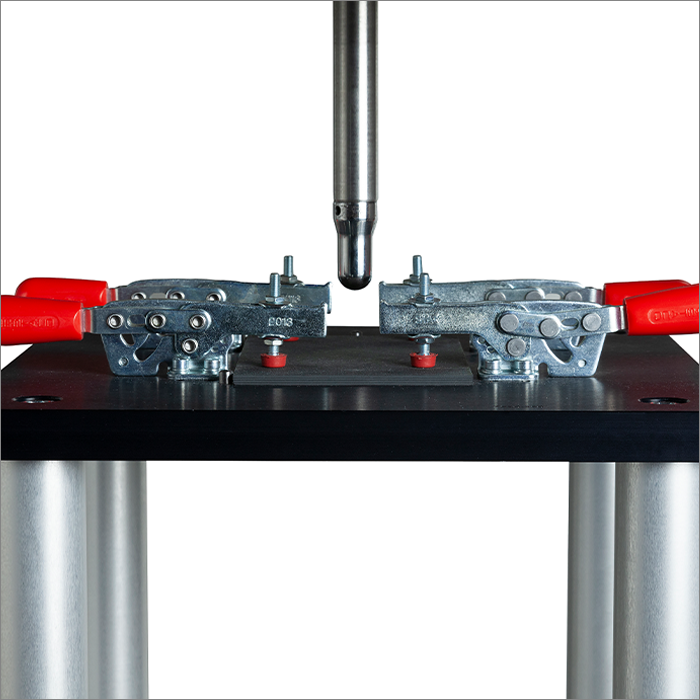

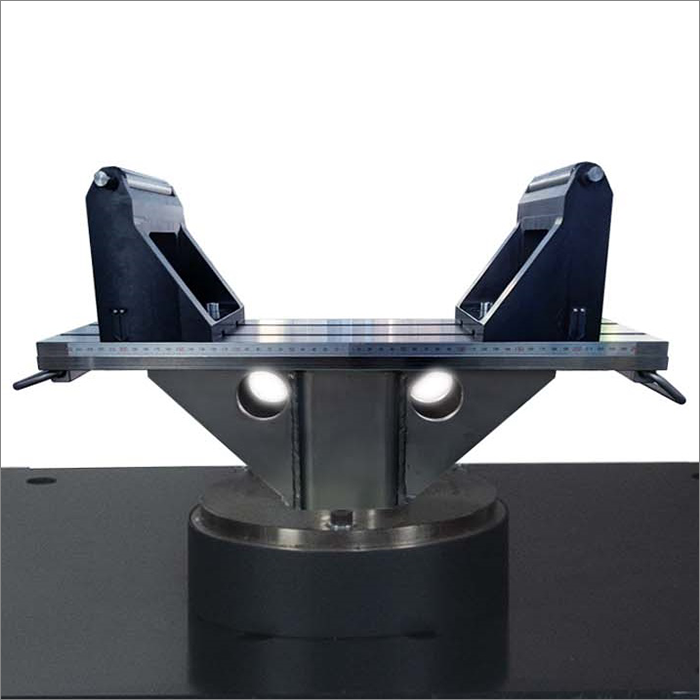

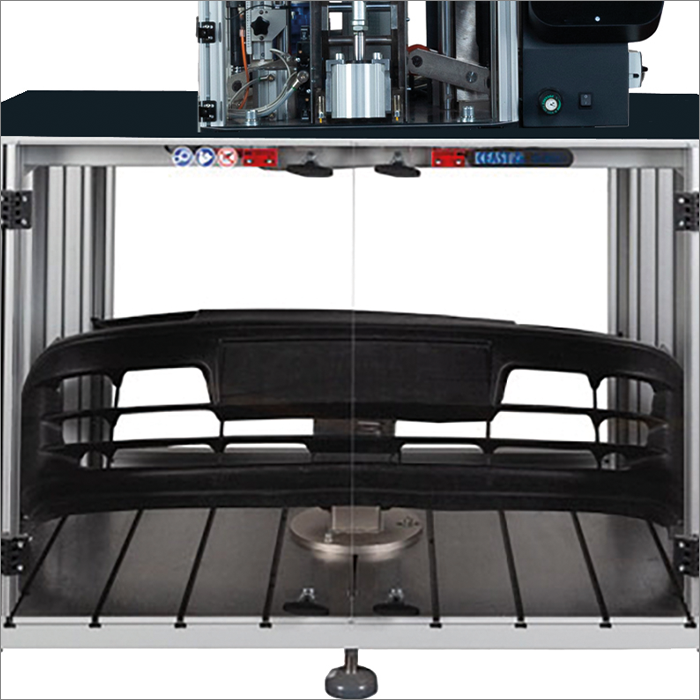

Enhance your Instron drop weight impact testing machine's versatility with a wide range of easily changed supports, masses, fixtures and accessories for puncture resistance test, tensile impact test, and wedge peel impact test along with compressive and component test

Move from task to task: easily share test methods and results within your Company or your Customers with Bluehill Impact file management system

SMARTER

Drop Weight Impact Testing Integrated Innovations for Advanced Performances

Extended Capabilities

Instron drop weight impact testing machine energy capacities and test space meet the most commonly performed impact test methods specific in Raw Materials Industries, Automotive, Aerospace-Aviation, Defense, Electronics and Consumer Products over a wide range of materials

Handle the Most Demanding Analysis

The 9450 drop weight impact testing machine capabilities can be expanded to include 24 m/s impact velocity, extra wide test chambers and high-speed cameras to never miss an impact test event

Faster Time to Market

With automated testing, newly developed materials can be continuously tested and validated. The reduction in testing cycles allows your Company to bring your products to market faster

SAFER

Drop Weight Impact Testing for Enhanced Operators Safety

Your investment is safe: components have been designed for a long service life and life tested to withstand thousands of impacts at the most severe condition without damage

High resolution data acquisition chain – engineered by Instron - ensures the accuracy of the force measuring system. It can be verified at the customer site and is verified at the factory following accredited procedures

A fully enclosed design with integrated safety circuits that disable the system automatically whenever an enclosure door is open protect operators

Impact Testing Machine Parts, Accessories and Options

|

|

|

||

|

9440

|

9450

|

9450 with Large Base

|

||

| Energy Range | J ft-lb |

0.3 - 405 0.22 - 299 |

0.59 - 1800 0.44 - 1330 |

0.59 - 1800 0.44 - 1330 |

| Impact Velocity |

m/s ft/s |

0.77 - 4.65 2.53 - 15.3 |

0.77 - 24 2.53 - 78.7 |

0.77 - 24 2.53 - 78.7 |

| Drop Height |

m in |

0.03 - 1.10 1.18 - 43.3 |

0.03 - 29.4 (equivalents) 1.18 - 1160 (equivalents) |

0.03 - 29.4 (equivalents) 1.18 - 1160 (equivalents) |

| Machine Dimensions (w x d x h) |

mm in |

985 x 610 x 2620 38.7 x 24 x 103 |

1015 x 866 x 3180 40 x 34 x 125.2 |

1520 x 940 x 3330 60 x 37 x 132 |

| Machine Weight |

kg lbs |

340 749 |

775 1708 |

1200 2646 |

| Test Area Dimensions (w x d x h) |

mm in |

490 x 450 x 565 19.3 x 17.7 x 22.2 |

700 x 720 x 570 27.5 x 28.3 x 22.4 |

1200 x 730 x 745 47.2 x 28.7 x 29.3 |

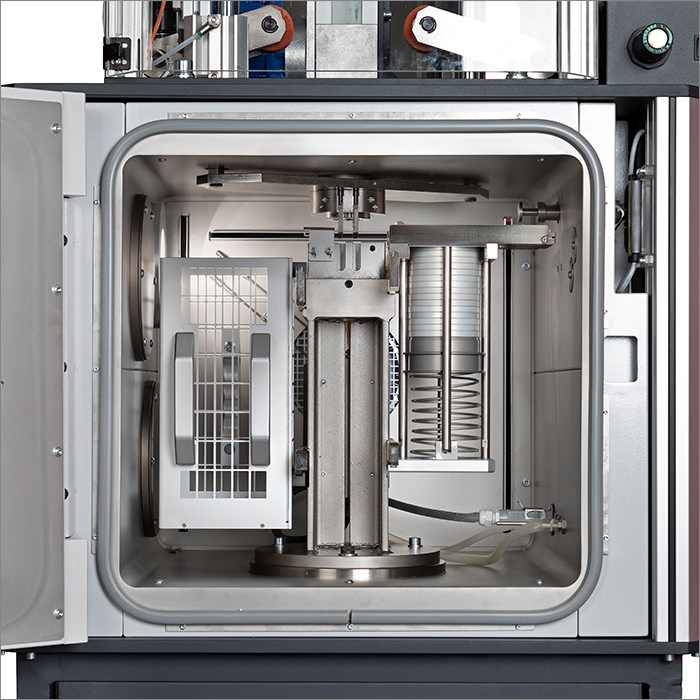

| Test area dimensions with thermostatic chamber (w x d x h) |

mm in |

370 x 300 x 495 14.6 x 11.8 x 19.5 |

550 x 540 x 500 21.6 x 21.3 x 19.7 |

550 x 540 x 500 21.6 x 21.3 x 19.7 |

| Compressed air supply | bar psi |

6 to 10 72.5 |

6 to 10 72.5 |

6 to 10 72.5 |

Extras

Drop Weight Impact Tester Know How